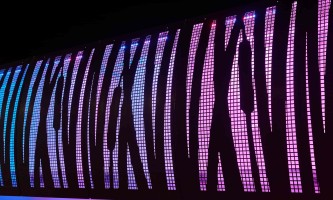

Belfast Bridge Facade

Challenges

This prestigious civil construction project came with some challenges that ENI and all parties involved were keen to solve.

As manufacturers of the facade, we needed to make sure the aluminium panels wouldn’t turn into a safety hazard by blinding drivers. The concrete structure of the bridge was convex, which meant our bracketing system needed to be flexible for an uneven surface.

Design for manufacturing

With those challenges in mind, our design team was heavily involved in the facade design process. Our engineers ensured all components are optimised for manufacturing and met the project’s safety requirements.

Fabrication & delivery

Once the CAD designs were locked in, we produced high quantities of panels and brackets to meet the project roll-out.

With our logistics service, we delivered individual components to the work site and supported Fulton Hogan with installation.